I started playing with LED grow lights three years ago when I bought three small LED spotlights from a vendor I met at the Cincinnati Flower Show. My initial approach to using the lights was very haphazard. I mainly used the spots to augment natural light from the south facing glass wall in the sunroom for starting vegetable seedlings in the spring.

The results for enhancing plant growth were noticeable and LEDs are way easier to work with than fluorescents and other lights. I didn’t like the spots, particularly, because they each had a noisy fan, but I was happy to have discovered them, nevertheless.

Geoff and Anneliese met Larry Schack, the owner of Sunshine Systems and other people from his firm at the 2009 Chicago Flower Show. Larry and the folks at Sunshine Systems are LED light experts with a superior line of lighting products. Both Geoff and I have tested their main light products and we are impressed enough to now sell them on our website.

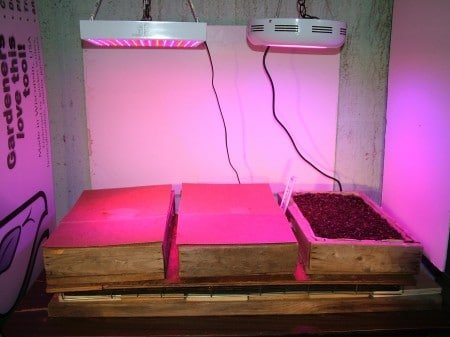

Last year for my initial trial of these lights I hung them in an out of the way spot in the basement. I had my heat mat and flats on the floor and it was not a good setup. I didn’t have room to manipulate the lights or the flats easily. So this year I cleaned out a back wall next to the furnace and set up a 24″ x 48″ folding table. I screwed in some eye hooks to the rafters to hang the lights. The GlowPanel 45 LED is the square light panel on the left in the picture and the GrowUFO LED is the round light on the right. Geoff and I used both these lights with great success. I just started seeds, but Geoff has been getting year round production out of them and I’m about to do the same.

I have the heat pad resting on a solid bed of 2 x 4’s and above that a solid bed of cutoffs leftover from the CobraHead tool displays we make. I’ve got dozens of these 6 1/2″ x 8″ x 3/4″ plywood blocks. They come in handy for lots of things. Above the heat mat I’ve got a solid sheet of 1/2″ plywood. I can use more small cutoffs for spacers above the heat mat and plywood if the flats get too hot.

I’ve got the 2 lights set up to one timer. I’ll probably do 14 hours on and 10 off for the lettuces and other greens I have planted, but I’ll do some reading up on optimal light times, too.

The heat mat is on a separate timer and is set up to be on only for a half hour, four times a day to start. The heat mat thermostat gave out long ago. If I just left it on it would take soil temperatures in the flats to well over a hundred degrees, so I have to monitor it and keep its heating potential corralled with the timer. The furnace itself throws out a lot of heat, so I think this is going to be a very good setup and I won’t need all that much heat from the mat. Unlike fluorescents and other lights, the LEDs put out almost no heat, so auxiliary heat is often necessary at least at the seed starting stage.

I’ve got three sheets of white foam sheeting from old signage to bounce some light back to the plants – one is an obsolete CobraHead sign, not quite white, but still with some good reflectivity.

The set up holds 3 of my 11″ x 19″ flats close to perfectly. There is a little extra room for some cups or smaller pots, too. It’s easy for me to slide the flats in and out to move them around, to rotate them in the light, to harvest, or to change them out.

I’ve seeded all three flats; two with various salad mixes and Asian Greens and one with basil and spinach. I hope to keep them in production until I start my regular seeds in March. I have the lights on to help germinate the lettuce, but I’ve cut some cardboard covers for the flats that work better than newspaper to hold the moisture in the flats and to keep light out when I don’t want light.

I expect to be writing about the good lettuce and greens we are harvesting indoors while its freezing outside, very soon.

the LED lights look pink… I would think that white would be better or is it just the picture?

It would be nice to have basil all year ’round.

The LED’s we are using contain arrays of mixed red and blue bulbs. The light cast is pink and kind of weird looking and probably would be out of place for lighting house plants. Most LED light setups sold for growing have a mix of red and blue bulbs. Some are mixed with white LED bulbs as well. The red and blue lights enhance foliage growth and outperform a solid white light. There are numerous combinations of light patterns that can be made available, and LED bulb arrays can be designed for very specific plant light needs.

The LEDs we sell are set up for enhanced foliage growth, especially good for kicking off seedlings to a fast start and pumping out a lot of leaf. They have performed exceptionally well in the tests we’ve done, so far. We will be offering straight white light bulbs, soon. These will be fine for many house plants, but if you want basil year round or you want to jump start your tomato seedlings, the red/blue combinations work best.

Looks like the perfect set up for my Christmas list! Do either of you have a favorite way of watering your flats?

Hi Chris, I just keep water in a plastic bottle by my flats and check the the moisture of the flats at least daily. I dribble the water through my fingers closed over the top of the bottle. I can control the water flow down to drops this way. I like this method because I can get a lot of water quickly into the flats when they need a big drink without washing out my seeds and seedlings.